Nov. 04, 2025

A nitrogen room can sealing machine replaces the air inside cans with nitrogen before sealing, significantly extending shelf life and preserving quality. These machines are essential for packaging products sensitive to oxygen, like food and pharmaceuticals. In this article, we’ll explore how they work, their benefits, and their applications across various industries.

Nitrogen room can sealing machines use nitrogen gas to create airtight seals, preventing contamination and extending shelf life for products sensitive to oxygen.

Customization options are crucial for sealing machines, allowing them to accommodate different can types and enhance packaging efficiency across various industries.

Regular maintenance and selecting a quality manufacturer, like Guangzhou Full Harvest Industries, are essential for ensuring effective operation and reliability of can sealing machines.

Nitrogen room can sealing machines are specialized devices used in packaging that utilize nitrogen gas to create a hermetic seal. Key features include:

The sealing process prevents contamination and significantly extends the shelf life of various products.

Precision sealing technology creates a secure, airtight seal, preventing leakage or contamination and maintaining the quality of the packaged goods.

Designed for high-speed production environments, these machines offer efficient sealing of numerous cans in a short timeframe.

These machines operate within a vacuum room, where nitrogen gas replaces the air inside the can before sealing. This process is vital for products that are sensitive to oxygen, such as food and pharmaceuticals. The use of nitrogen not only preserves the product’s quality but also enhances its shelf stability.

With their advanced technology and high efficiency, nitrogen room can sealing machines are indispensable in modern packaging operations.

The use of nitrogen gas in can sealing brings a plethora of benefits, including:

Its ability to replace oxygen inside the can, reducing residual oxygen levels to around 3-5%, which is essential for preserving product integrity.

Helping maintain medication stability in the pharmaceutical sector by protecting against moisture and oxidation.

Creating an inert atmosphere inside the cans, significantly reducing spoilage from oxygen exposure.

Prolonging the freshness of food products by reducing oxygen-related spoilage.

Another critical advantage of nitrogen sealing is the combination of vacuum pressure and nitrogen gas, which effectively minimizes oxygen levels inside the cans and enhances product longevity. Nitrogen flushing helps maintain low oxygen levels required for extending the shelf life of various products and reducing oxidative damage.

Additionally, the airtight seals provided by these sealing machines are crucial for improving overall product quality by eliminating oxygen and preserving taste and aroma. This combination ensures that products maintain their original taste and freshness for a longer duration.

The benefits of nitrogen room can sealing extend across various industries, enhancing product quality and ensuring shelf stability. Whether it’s food, beverages, or pharmaceuticals, using nitrogen in the sealing process offers a reliable solution to prevent spoilage and maintain product quality.

Sealing machines can come in various types, each designed to meet specific packaging needs. One popular type is rotary can seaming machine, which is favored in high-speed production environments. These machines:

Operate by rotating the containers during sealing

Allow for quick and efficient processing

Are particularly advantageous in large production settings where speed and efficiency are paramount.

On the other hand, non-rotary can sealing machines keep the cans stationary during the sealing process. This stationary approach is beneficial for packaging liquid products, as it minimizes the risk of spillage and damage. Non-rotary machines are ideal for products that require careful handling and precise sealing, making them a versatile option for various packaging applications.

Both types of machines offer unique advantages, catering to different production needs and ensuring optimal sealing performance.

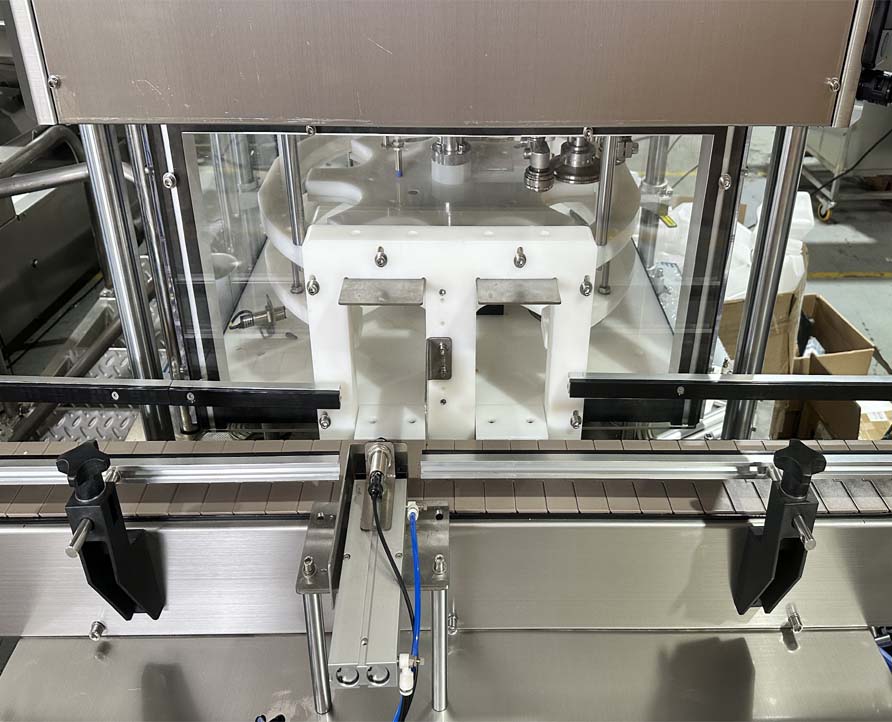

To ensure a proper seal and maintain the quality of packaged products, nitrogen room can sealing machines are equipped with several key components. These include seaming rollers and chucks made of Cr12 die steel, which enhances durability and effectiveness in creating a hermetic seal. The precise engineering of these components is crucial for the sealing process, ensuring that the lid is securely attached to the can.

Additionally, the integration of vacuum pressure and inert gas, such as nitrogen, plays a vital role in achieving an airtight seal, further protecting the product’s integrity.

Seaming rollers are at the heart of the can sealing process. These components are responsible for exerting the necessary pressure to ensure that the lid is securely attached to the can. The precision and durability of seaming rollers are crucial for achieving a hermetic seal, which prevents any air or contaminants from entering the can. Made from Cr12 die steel, these rollers are designed to withstand the rigors of high-speed production environments while maintaining their effectiveness over time.

The role of two seaming rollers extends beyond just sealing; they also ensure that the seam is uniform and strong enough to withstand handling and transportation. Applying consistent pressure during the sealing process, seaming rollers create a reliable seal that preserves the product’s quality and extends its shelf life, utilizing advanced seaming equipment.

Their importance in the overall sealing process cannot be overstated, as they are integral to the machine’s ability to deliver a secure and airtight seal.

The dimensions of the base plate and chuck are critical for the effective operation of a nitrogen room can sealing machine. These components must correspond to the can’s diameter to ensure proper sealing. The size and shape of the base plate and chuck determine the stability and positioning of cans during the sealing process, which is vital for achieving a consistent and secure seal. Accurate alignment with the can’s specifications guarantees that the sealing process is both efficient and effective.

Customizing the base plate and chuck to accommodate various can sizes is essential for maintaining the versatility of the sealing machine. Different products may require different can dimensions, and the ability to adjust these components ensures that the machine can handle a wide range of packaging needs.

This customization enhances the machine’s ability to provide a reliable seal across various can types and sizes, contributing to the overall efficiency of the packaging process.

Vacuum pressure is a crucial element in creating a hermetic seal within a nitrogen room can sealing machine. By reducing the internal pressure inside the can, vacuum pressure assists in maintaining the integrity of the seal formed. This process prevents air from entering the package, which is essential for preserving the product’s quality and extending its shelf life. The combination of vacuum pressure and inert gases, such as nitrogen, enhances the sealing process by eliminating oxygen from the can.

Inert gases like nitrogen play a vital role in the sealing process by replacing oxygen, thereby preventing oxidation and spoilage. Using nitrogen not only extends the product’s shelf life but also helps maintain its flavor and nutritional value.

Integrating vacuum pressure with the injection of inert gases, manufacturers achieve a higher quality seal that enhances product durability and minimizes spoilage during storage and transport.

Nitrogen room can sealing machines have a wide range of applications across various industries. In the food industry, these machines are essential for extending the shelf life of perishable goods by preventing oxidation. They are used for sealing a variety of food products, including canned fruits and vegetables, ensuring prolonged freshness and quality. For snacks like nuts, nitrogen sealing helps maintain a stable shelf life and product integrity.

In the pharmaceutical sector, nitrogen room can sealing machines play a crucial role in preserving the integrity of sensitive products. By creating an oxygen-free environment, these machines ensure that medications remain stable and effective over time. Additionally, they are used for packaging dry fruit, preventing moisture absorption and maintaining the quality and freshness of products like raisins and dried apples.

The versatility of these machines makes them invaluable across multiple industries, providing reliable packaging solutions for a variety of products.

Customization options for nitrogen room can sealing machines are essential for optimizing the sealing process and enhancing product protection. These options allow manufacturers to tailor the sealing process to specific can types, ensuring efficiency and effectiveness in packaging.

Whether it’s adjusting the sealing pressure for tinplate cans or customizing the dimensions for round cans, these options contribute to better branding, product safety, and overall packaging form quality.

Customization is particularly important for round cans and tinplate cans. For round cans, customization can include specific seam types and dimensions that align with product requirements, facilitating a stable and secure seal. The thickness and coating of tinplate cans can be adjusted to improve durability and resistance to rust, further enhancing product protection. These strategic customizations not only improve sealing effectiveness but also enhance the shelf life and integrity of the packaged products, including those utilizing automatic tin.

Both round and tinplate cans benefit from customization techniques that contribute to better branding and product safety. Full-color printing on various round cans allows brands to create visually striking designs that improve shelf presence. By optimizing the sealing process through targeted customizations, manufacturers can ensure that their products remain fresh and appealing to consumers.

Plastic and aluminum cans offer various customization options that enhance their aesthetic appeal and functionality. For plastic cans, customization can include different colors and shapes tailored to specific product requirements. Custom finishes and printing options are available for aluminum cans, allowing for vibrant graphics and improved brand visibility. These flexible decoration options, such as shrink sleeve labeling, enable manufacturers to create attractive and distinctive packaging that stands out on the shelves.

The ability to customize plastic and aluminum cans enhances their versatility and appeal across different product categories. Whether it’s for beverages, snacks, or other consumer goods, these customization options ensure that the packaging is both functional and visually appealing, meeting the needs of modern consumers.

Sealing methods for paper cans and glass containers are crucial for ensuring product safety and extending shelf life. For glass containers, induction sealing is often used to create airtight seals that preserve the product’s freshness and quality. These containers can be customized with various sealing methods to ensure that they meet the specific needs of the product being packaged.

Paper cans offer a sustainable packaging solution that can be customized to enhance product protection and appeal, similar to tin cans. Customizing the can body and lid to fit different product types ensures that the packaging process is efficient and effective, much like a container designed for optimal use.

By utilizing advanced sealing techniques, manufacturers can ensure that their products remain safe and fresh for longer periods, meeting the demands of consumers for both quality and sustainability. A sealer can enhance these sealing methods.

Automatic can sealing machines are a game-changer in the packaging industry, offering several key benefits:

Significantly enhancing efficiency

Reducing labor costs

Requiring minimal operator interaction, making them suitable for high-volume production environments

Enabling higher production speeds

Ensuring a consistent and reliable seal for each can with fully automatic operation.

This automation not only improves the overall efficiency of the packaging process but also helps to enhance efficiency by reducing the need for processed manual labor, leading to lower labor expenses.

Advanced automatic can sealing technology enables precise control over the sealing process, optimizing material usage and ensuring that each can is sealed perfectly. By integrating these machines into production lines, manufacturers can significantly enhance their packaging operations, resulting in improved product quality and extended shelf life. The benefits of automatic can sealing machines make them an invaluable asset for any high-volume packaging operation.

Regular maintenance and support are crucial for ensuring the long-term operation and effectiveness of sealing machines. Implementing a preventive maintenance schedule is essential, much like regular car maintenance, to keep the machinery running smoothly and efficiently. Operators can perform basic maintenance tasks, which helps them become familiar with the equipment and identify potential issues before they escalate. This familiarity not only improves the operation of the machines but also extends their lifespan, reducing the likelihood of unexpected breakdowns.

Opting for durable and robust models can save costs in the long run due to reduced maintenance needs. Regular maintenance ensures that the sealing machines continue to deliver effective packaging solutions, maintaining product quality and efficiency in the production process. Moreover, having access to technical support and a readily available list of spare parts can minimize operational interruptions and ensure that any issues are promptly addressed.

Selecting the right machine manufacturer is a critical decision that can significantly impact the efficiency and reliability of your packaging operations. Key factors to consider include:

Budget: High-quality can sealing machines typically come with a higher price tag.

Quality: Investing in quality equipment can lead to long-term savings by reducing maintenance costs and downtime.

Technical Support: Choose manufacturers that offer responsive technical support, which can significantly reduce downtime when problems occur with sealing machines.

Having a readily available list of spare parts categorized by wear can ensure quick replacements and minimize operational interruptions. Staying updated with the manufacturer about software and equipment upgrades can prevent issues related to outdated technology in sealing machines.

Additionally, warranties and support terms should be carefully reviewed, as they provide security in case of mechanical failures. When selecting a manufacturer, consider:

Machine price

Quality assurance

Support services

Warranty provisions

This will help ensure you make the best choice for your packaging needs.

Successful implementations of nitrogen room can sealing machines across various industries have led to increased shelf life, improved product quality, and enhanced customer satisfaction. These machines have proven beneficial in diverse sectors, from food and beverages to pharmaceuticals, showcasing their versatility and effectiveness.

Real-world examples highlight the tangible benefits that businesses have experienced after adopting this advanced sealing technology.

In the food industry, nitrogen room can sealing machines are extensively used to enhance product preservation and shelf life. For instance, a leading beverage company reported a 30% increase in shelf life for their canned drinks after implementing nitrogen room can sealing technology. This extension in shelf life not only improved product quality but also reduced waste and increased customer satisfaction.

Additionally, a popular food manufacturer switched to nitrogen sealing and experienced improved product integrity and taste preservation in their canned products. Utilizing nitrogen in the sealing process helps remove oxygen from the cans, significantly extending the shelf life and maintaining product quality.

The combination of rigorous sealing methods and nitrogen use allows food manufacturers to enhance packaging efficiency, reduce waste, and improve customer satisfaction. These examples demonstrate the substantial benefits that nitrogen sealing technology brings to the food industry.

In the pharmaceutical industry, nitrogen sealing techniques are implemented to ensure the integrity and longevity of sensitive products. For example, a pharmaceutical company reduced product spoilage by 25% by using nitrogen room sealing, ensuring the efficacy of their capsules. This reduction in spoilage not only improved product quality but also enhanced the company’s reputation for delivering reliable and effective medications.

These sealing machines play a crucial role in maintaining the efficacy and stability of sealed medications through nitrogen protection. By creating an oxygen-free environment, these machines ensure that medications remain stable and effective over time.

These success stories highlight the significant impact that nitrogen sealing technology has on the pharmaceutical industries, ensuring product stability and efficacy while meeting stringent international packaging standards.

When it comes to selecting a reliable and experienced manufacturer for nitrogen room can sealing machines, Guangzhou Full Harvest Industries stands out as a global leader. Specializing in can seamer machine, their engineers bring about 10 years of experience in the field. They assist customers in assembling complete production lines for can packaging, including can filling machines, can seamer machines, can capping machines, and labeling machines. Their comprehensive solutions cater to various industries, including food, beverage, pharmaceutical, and chemical sectors, with a focus on the seamer machine.

Guangzhou Full Harvest Industries is integrated with research and development, design, production, and sales, ensuring that they stay at the forefront of innovation and quality. Their commitment to development and continuous progress is unwavering, with product quality serving as their most powerful weapon and solid foundation for continuous development.

Choosing Guangzhou Full Harvest Industries allows you to leverage their expertise to meet packaging requirements and ensure the highest standards of product quality and efficiency.

In conclusion, nitrogen room can sealing machines are revolutionizing the packaging industry by ensuring product integrity, extending shelf life, and enhancing efficiency. From understanding the types and key components of these machines to exploring their applications across various industries, it’s clear that they offer substantial benefits. Customization options and automatic sealing further enhance their effectiveness, while regular maintenance and support ensure long-term operation. When selecting a manufacturer, Guangzhou Full Harvest Industries emerges as a reliable leader, offering comprehensive solutions and unmatched expertise. Embrace this advanced sealing technology to elevate your packaging operations to new heights.

Nitrogen room can sealing machines are designed to create airtight seals using nitrogen gas, effectively preventing contamination and enhancing the shelf life of packaged products. This method is essential for maintaining product quality in various industries.

Using nitrogen in can sealing effectively preserves product integrity by reducing oxygen exposure, thereby extending shelf life and preventing spoilage. This results in higher quality products for consumers.

There are two main types of can sealing machines: rotary and non-rotary. Rotary machines are designed for high-speed production, whereas non-rotary machines are better suited for sealing liquids to reduce the risk of spillage.

Automatic can sealing machines enhance efficiency by minimizing operator interaction, which lowers labor costs and greatly increases packaging speed. This streamlined process allows for higher production rates and improved overall productivity.

Regular maintenance is essential to guarantee the efficient operation and durability of sealing machines, as it minimizes potential problems and extends their overall lifespan.

No.3 Gongye South Road,Mingzhu Industrial Park,Conghua District ,Guangzhou City 510900,China

+86 20 3751 0321

FOLLOW US

Tel/ Fax: +86 20 3751 0321

E-mail: sales@gzfharvest.com

Add: No.3 Gongye South Road,Mingzhu Industrial Park,Conghua District ,Guangzhou City 510900,China